JLM Trains, L.L.C.

Resto Example

Anatomy of a Total Restoration

The following is an extreme example of a complete restoration. The item used is a Lionel #155 Freight Platform from around 1940. The item is complete, but has a great deal of pitted rust and major paint loss. Most people would consider it un restorable, but we’ve seen worse.

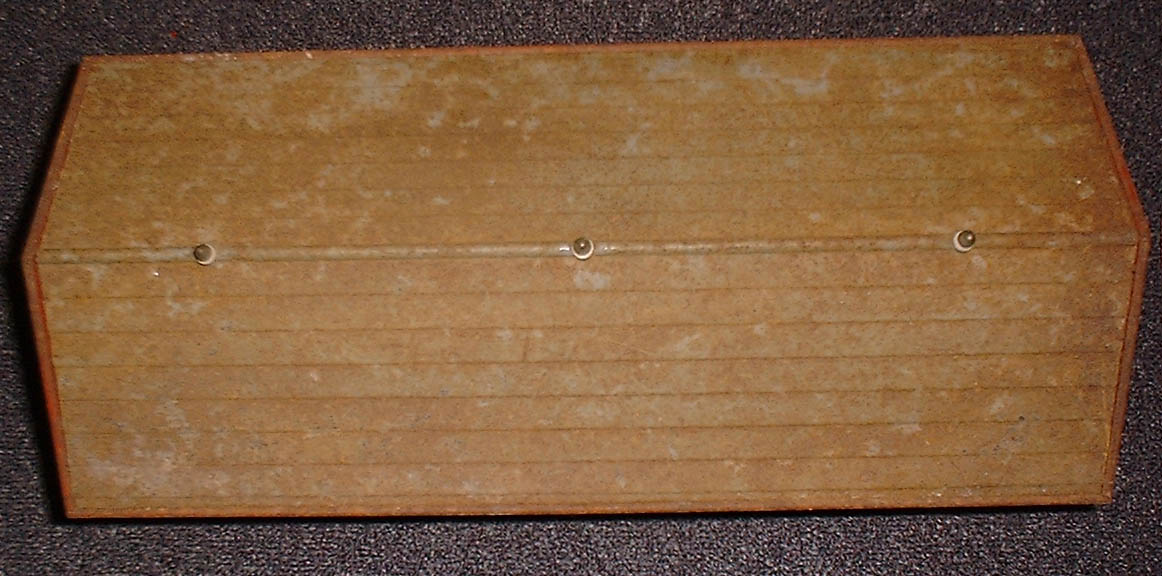

Above is the155 Freight Platform before restoration. Notice that it is complete and unbroken, but with major rust.

Some of the areas of the platform are rusted through.

The roof is missing almost all of it’s paint and has the worst rust problem.

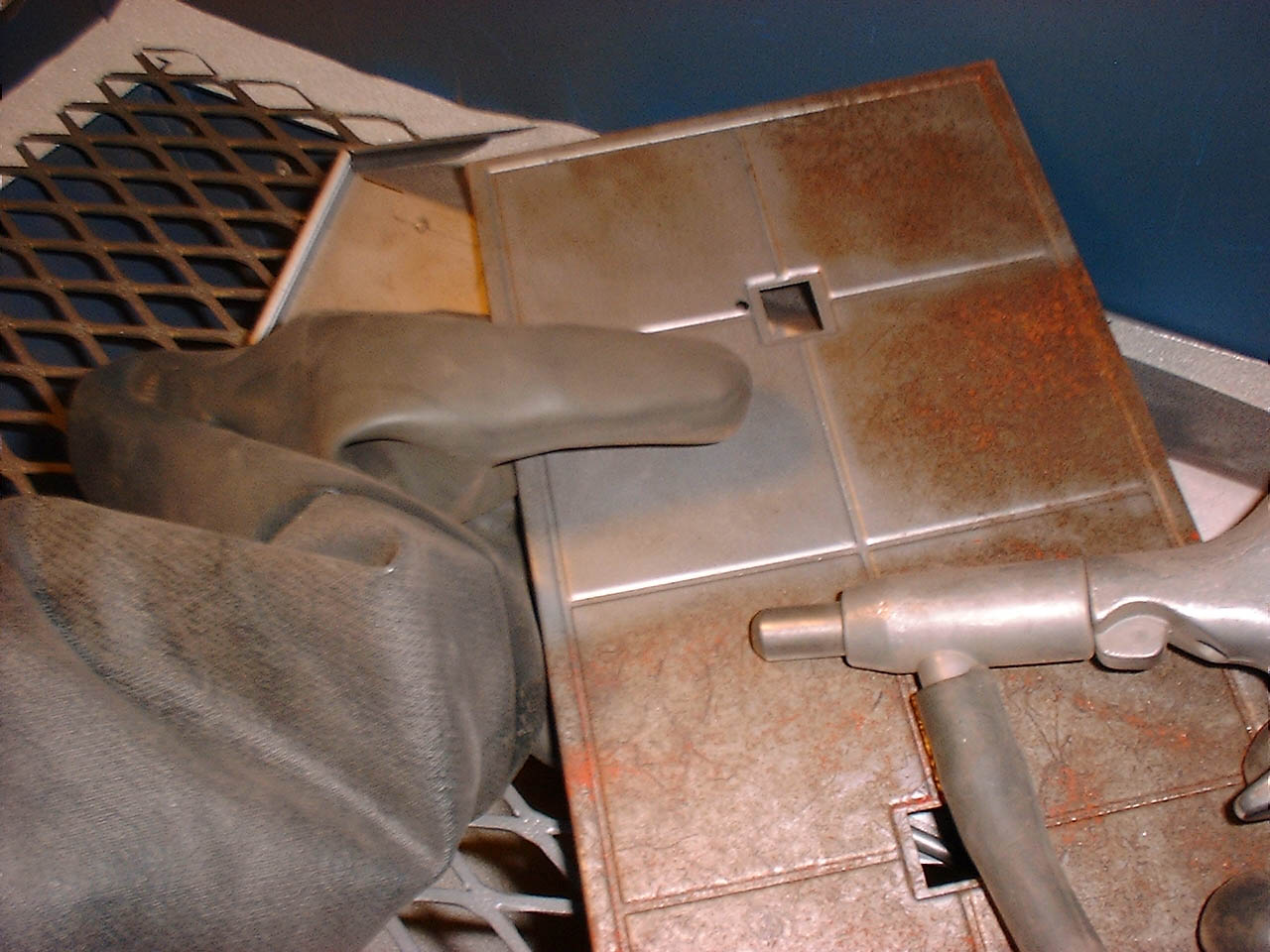

The item is completely disassembled. Although fairly simple in this example, some items tend to be a little more complex. This accessory is primarily held together with screws. Some pieces use folded tabs and slots, and still others are held together by soldering. We can work with all these assembly methods.

At this point all parts are tagged and boxed so that they stay together through the different stages of restoration. First, all painted parts will be stripped of paint and rust. The most effective method for this is glass beading. We have our own glass beading cabinets in our shop, so nothing has to be farmed out. This allows to control quality, costs and turnaround. But, most importantly, the pieces never leave our hands.

The photo above shows how effective the glass bead process is. All paint and rust can be removed this way. It leaves a surface finish that is conducive to paint adhesion.

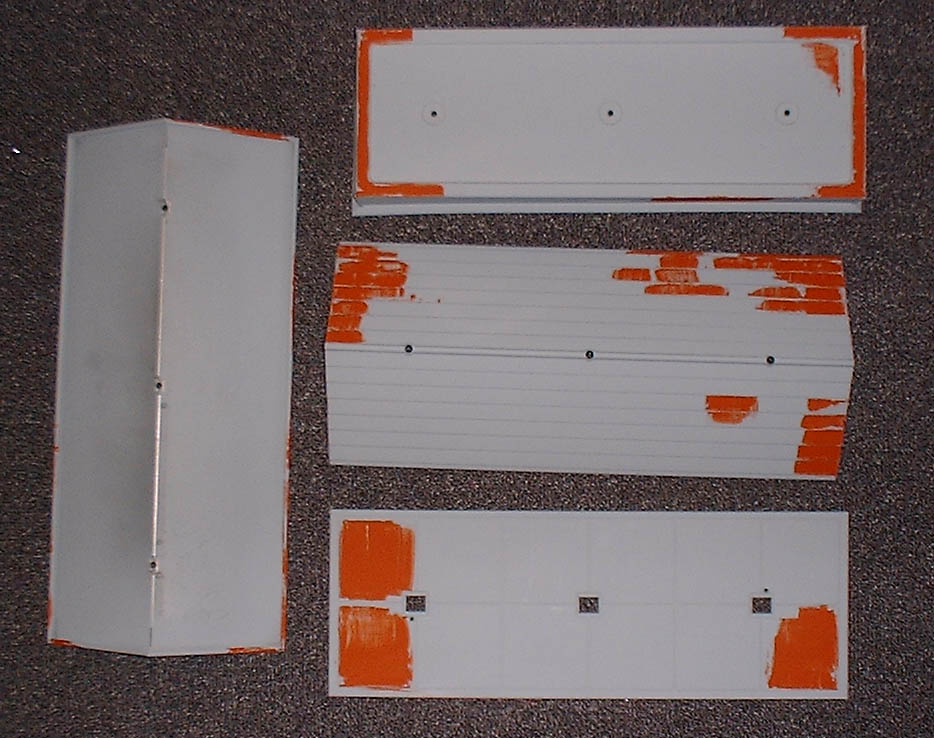

Above are the major components in the prime stage. The grey areas are spray primed, while the red areas are filled with a lacquer base spot filler. These pieces will require many coats of primer and spot filler to level the surface and cover the pits left from the rust. Each surface is sanded between each successive application of primer. This ensures a smooth surface for the paint to be applied to. Preparation before paint is 90% of the labor involved in a quality paint job.

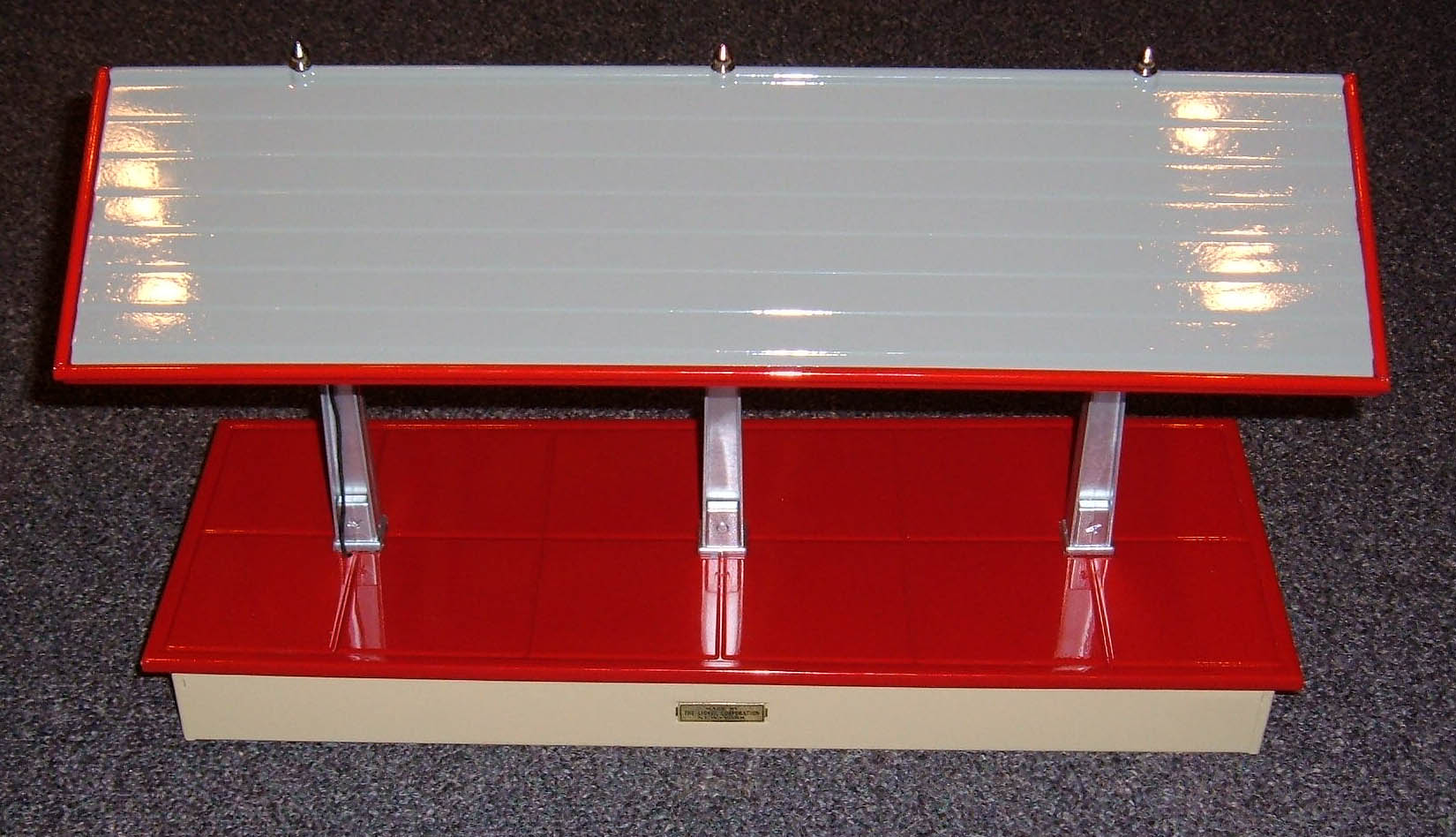

All of our colors are custom mixed automotive enamels. We use DuPont Professional Refinishing products. Almost exclusively, the coating will be Acrylic Enamel. We choose this type of paint for it’s durability, versatility and degree of gloss. We retain a database of paint mix codes, obtained over the years, so that colors can be matched accurately. Examples are taken from clean original pieces, computer matched, and the records kept. When we need the correct color, we have the formula available. Also, customers that send us an item to restore, then, years later, send another to be painted the same color, will receive a piece that matches the previous work.

All wiring has now been replaced, new light sockets and bulbs are added and the rooftop finials have been stripped and replated in Bright Nickel. Although a seemingly easy piece to restore, it required many hours of stripping, preparation, the application of four different topcoat colors and careful reassembly. The finished piece is now as nice or better than it was more than 65 years ago.

The brass plates on this piece needed to be restored also. This is something that we do on every restoration. If the item was lettered with rubber stamped lettering, we can re apply that also. Our rubber stamps are made by directly copying good, original pieces. The rubber stamps are then produced to our specifications. We do not use stock type. This ensures that the lettering will fit properly in the area that it was originally.